Features

● Embedded vision system

◆Template matching

◆Edge recognition

● Simple operation

◆7 'handheld tablet programming

◆Simple and professional dispensing programming interface

● High-precision motion control

◆Stepping motor with encoder feedback

◆Precision timing belt

● Optional functions

◆Laser height sensor

◆Needle position calibration

◆Low liquid level detector

◆Nozzle cleaner

Specifications

Specification | AR-300V | AR-400V |

Effective travel (X,Y&Z) | 255mmx300mmx100mm | 355mmx400mmx100mm |

Position resolution | 0.005mm※ |

Position repeatability | ±0.01mm※ |

Maximum speed | X/Y:=600mm/s; Z=250mm/s |

Z axis payload | 3kg |

Work-holder payload | 7.5kg |

Motion system | Stepping motor with encoder feedback, timing belt |

Dispensing Patterns | Dot, line, arc and user defined |

Software functions |

Vision fiducial and inspection, batch programming, matrix duplicate, height inspection, CAD input, Fids-on-the-fly and Jet on-the-fly |

Dimensions (L/W/H) | 540mmx450mmx525mm | 640mmx550mmx525mm |

Optional | Laser height sensor, Needle position calibration, Low liquid level detector, Nozzle cleaner |

*Using laboratory test method

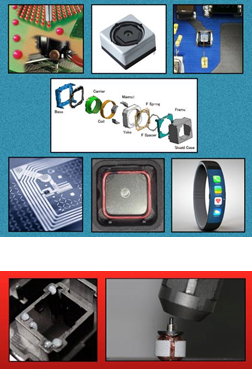

Typical applications

●Camera modules assembly

◆VCM

◆Lens Fixing

◆Lens Holder Adhesive Dispensing

◆Flip-chip Underfill for Image Sensor

●Fingerprint recognition

◆IC encapsulation

◆Chip underfill

◆Metal frame bonding

●Smart phone assembly

◆Sealing for Cover Frame

◆Chip Encapsulation and Underfill for FPC Assembly

●Acoustics Devices

◆Ear Phone, Speaker and Microphone Assembly

◆Speaker Frame and Membrane Assembly

◆Coil Assembly

●MEMS

◆Au Wire Encapsulation

◆Solder Paste Acoustical Seal

●Vibration Motor

◆Lids sealing

◆Weld pad protection